Mr. Michel, CEO of the company Armin Strom AG, with a tray of watches from the Skeleton series.

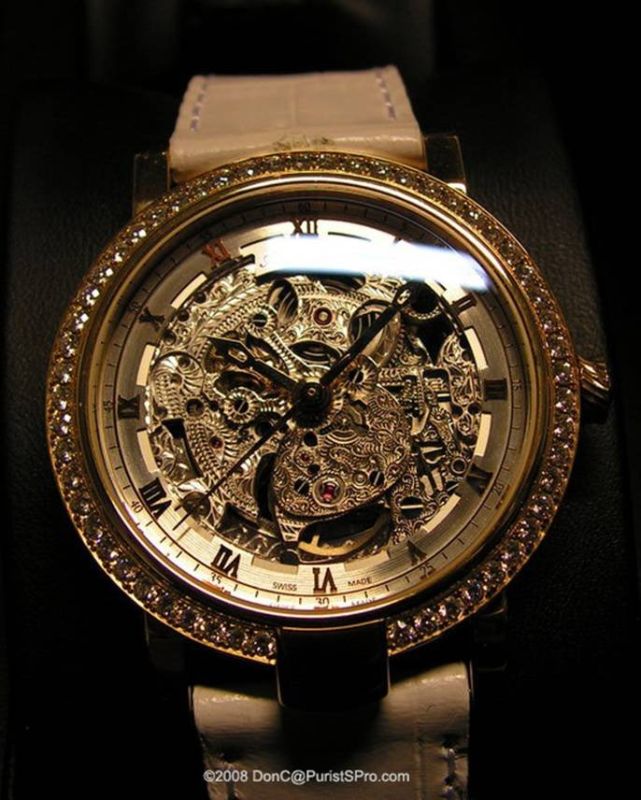

The cases are 39.2mm in dia. and 10.45 high. Here in white gold 18k

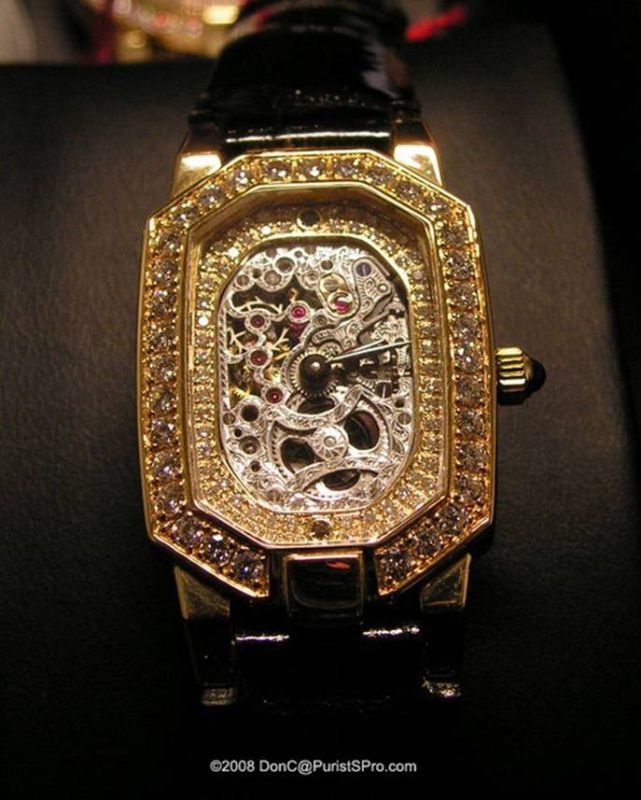

Yellow gold 18k set with a diamond set bezel.

A stainless steel prototype case.

The Skeleton Lady, 18k yellow gold set with 33 diamonds. The movement is an old stock Alpina from the 1930's. It enjoyed, of course, Armin Strom's personal attention.

Note the typical case and crown form. Here on a 18k white gold model with brushed front and back bezels and lugs.

A gold skeleton wrist shot. The size is right! And the distinctive crown winds very comfortably.

The Blue Chop automatic, 46.5mm dia. & 15.9mm high. The caliber is a hand engraved, partially skeletonized ValGranges.

The Blue Chip chrono.

The Blue Chip chrono.

The Blue Chip power reserve.

Blue Chip manual wind based on the hard working 6498

The Blue Chip manual on a bracelet.

The Elegance models I saw were all prototypes. Here in steel.

The Elegance models I saw were all prototypes. Here in steel.

That these are prototypes is our luck. Here we can see the difference between the original old stock Swiss caliber from the 1970s and the skeletonized and engraved resulting movement.

That these are prototypes is our luck. Here we can see the difference between the original old stock Swiss caliber from the 1970s and the skeletonized and engraved resulting movement.

A men's Elegance in rose gold.

Now we have seen the watches, let's take a little stroll around the shop.

A men's Elegance in rose gold.

Now we have seen the watches, let's take a little stroll around the shop.

Here is Mr. Strom's working space. The front bench for skeletonizing, the back bench for watchmaking, assembly and regulation.

Here is Mr. Strom's working space. The front bench for skeletonizing, the back bench for watchmaking, assembly and regulation.

Here on the bench are all the skeletonized and engraved parts of a custom watch, nr.2 of 2.

Here on the bench are all the skeletonized and engraved parts of a custom watch, nr.2 of 2.

I am guessing that this will be cased in a gold case seeing the partial gold plating of the movement.

I am guessing that this will be cased in a gold case seeing the partial gold plating of the movement.

The nr.1, Is that not spectacular ?

The nr.1, Is that not spectacular ?

It seems that in skeletonizing one uses a file or two

It seems that in skeletonizing one uses a file or two

Here a completed men's skeleton, the original manual winding form movement from the 1930's.

Here a completed men's skeleton, the original manual winding form movement from the 1930's.

Now we move to the engravers shop

Now we move to the engravers shop

An automatic rotor with the engraving partially finished. For engraving the parts are held in a kind of heat softening mastic, the vise is mounted on a sphere to allow complete flexibility.

An automatic rotor with the engraving partially finished. For engraving the parts are held in a kind of heat softening mastic, the vise is mounted on a sphere to allow complete flexibility.

Working under a microscope looks tiring, but it is the only way to be able to have the visibility needed.

Working under a microscope looks tiring, but it is the only way to be able to have the visibility needed.

Here the edges of a bridge are being cleaned up with an abrasive stick. The bridge is screwed on a handle to be able to hold it well. A piece of hardwood in the watchmakers vice serves as a support.

Here the edges of a bridge are being cleaned up with an abrasive stick. The bridge is screwed on a handle to be able to hold it well. A piece of hardwood in the watchmakers vice serves as a support.

These bridges all need to have their edges finished. She still has a certain amount of work to do today.

These bridges all need to have their edges finished. She still has a certain amount of work to do today.

In January Armin Strom will be introducing a new model, "Elements". Here Mr. Michel is modeling a prototype.

Источник: http://mob.watchprosite.com/show-for...ti-479471/s-0/

In January Armin Strom will be introducing a new model, "Elements". Here Mr. Michel is modeling a prototype.

Источник: http://mob.watchprosite.com/show-for...ti-479471/s-0/